PREFER STONE

Connecting Vision with Stone

QUALITY CONTROL

We at Prefer Stone, provide our global clients with a comprehensive view of what top-quality granite production entails through exceptional transparency in all aspects of our operations. Our commitment to openness allows customers to trust that every step of the process is clear and accountable.

By identifying and addressing potential issues in real-time, we ensure swift problem resolution, preventing disruptions and maintaining the high standards our clients expect. Our granite quality control practices are designed to meet buyers’ specific requirements, reducing the risks associated with imports and ensuring that the final product adheres to strict specifications.

We perform thorough quality inspections at every stage of production, starting from pre-production checks, through the manufacturing process, and concluding with pre-shipment quality assessments. Additionally, we supervise container loading to ensure that all granite slabs, tiles, and products are handled carefully, minimizing the risk of damage during transport and ensuring a smooth delivery to our clients. This end-to-end approach guarantees a flawless experience and consistently high-quality products.

We adhere to Internationally Acclaimed Quality Control Procedures

Visual Inspection

Visual inspection of granite slabs is a critical step in quality control, ensuring that the products meet aesthetic and structural standards before they reach the customer. This process involves several key This process involves several key elements: elements such as Surface Assessment, Color Consistency and Edge and Corner Examination

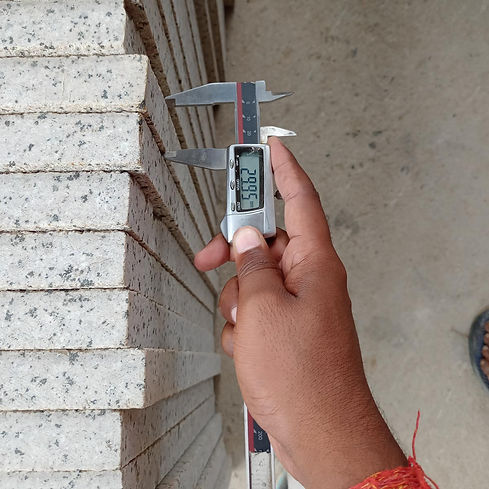

Dimension Inspection

Dimension inspection of granite slabs is a vital quality control process that ensures the slabs meet specified measurements and tolerances. This process includes several key aspects such as Thickness Consistency, Flatness and Straightness and Edge Alignment using precision tools Precision tools such as calipers, measuring tapes, and laser measuring devices are used to accurately assess the dimensions of each slab, including length, width, and thickness.